How do I efficiently use Stock Logs?

Stock Logs are a crucial tool in Fixably, allowing you to view audit trails across several different data points. This article is a guide to the information available in Stock Logs and how to use it effectively.

- Release Notes

- Newly Released Features

- Getting Started

- Roles & Permissions

- Manifests

- Order Management

- Automations

- Employee Management

- Customer Management

- Customer Portal

- Stock Management

- Part Requests

- Price Lists

- Invoicing

- Reporting

- Custom Fields

- Integrations

- GSX

- Shipments

- Service Contracts

- Configuring Your Environment

- Incoming Part Allocation

- Appointment Booking

Table of Contents

What are Stock Logs?

Using Stock Logs

Stock Log Types

What are Stock Logs?

Stock Logs provides an audit trail for Products, Serial Numbers, or Stocks, including:

- Date and time the product was added to Stock

- Stock Location

- Stock movements

- Serial or IMEI numbers

- Quantity

- Purchase Order

Using Stock Logs

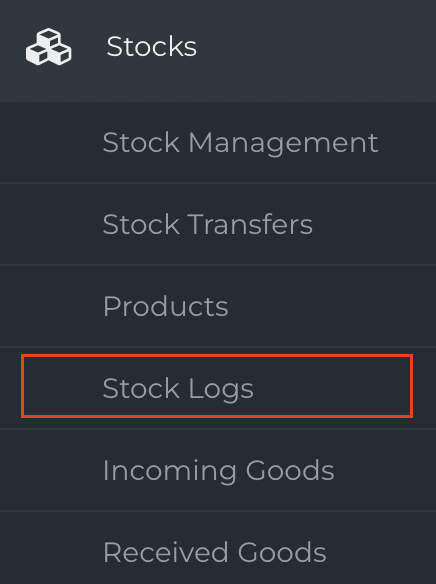

- From the Navigation Sidebar, click Stocks and then Stock Logs.

-

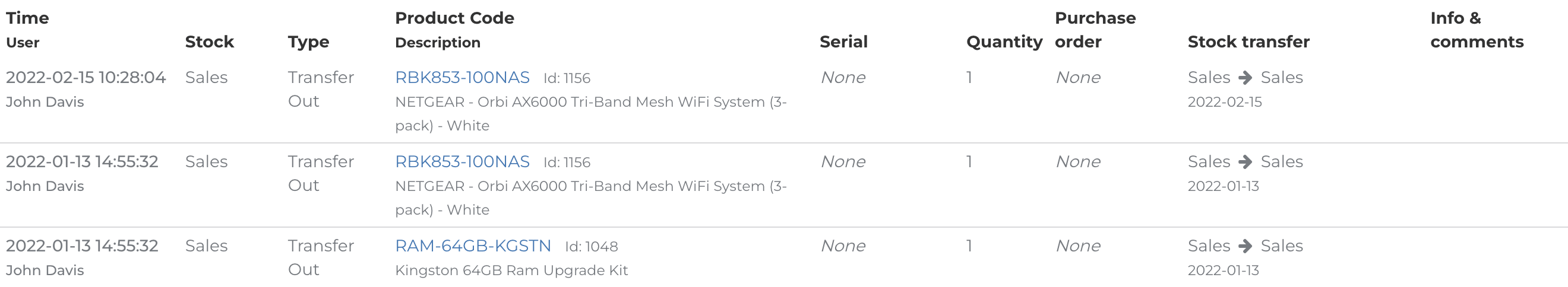

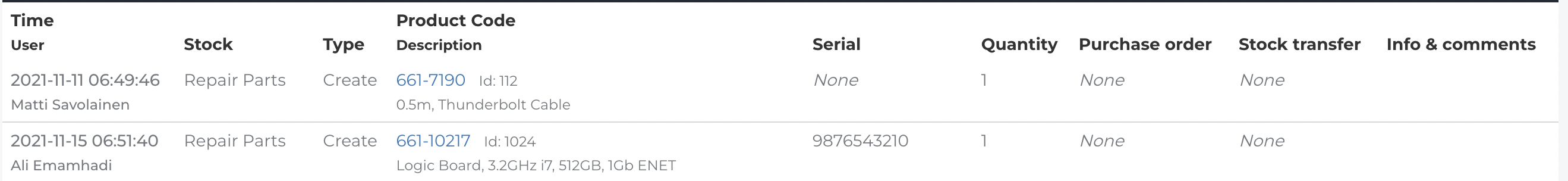

Stock Logs will display a list of each Stock related entry in your environment.

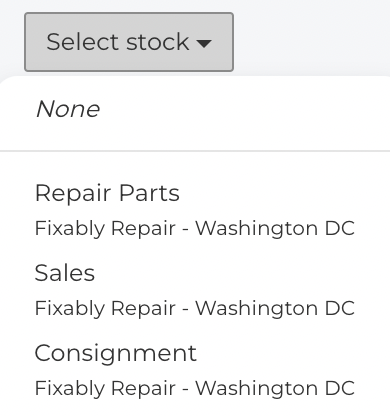

- If you have multiple Stocks, you can filter using the Select Stock drop-down menu.

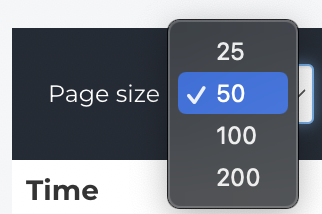

- Use the Page Size drop-down menu to select how many entries you would like to see per page.

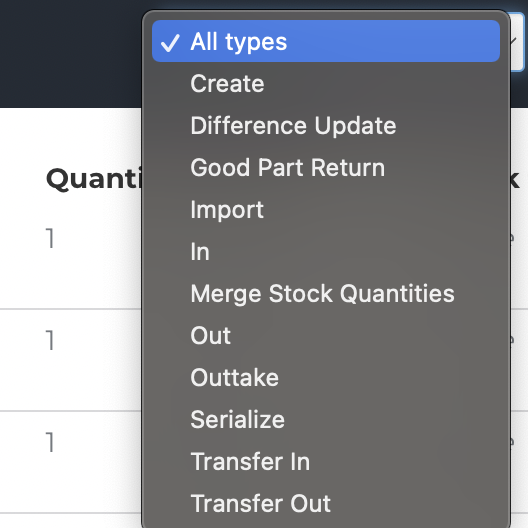

- Stock movements have multiple Types. Select the Type from the drop-down menu if you are looking for a specific action or situation.

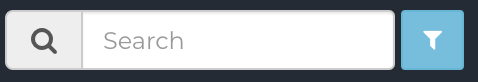

- You can also search for Product or Serial Number.

Stock Log Types

Stock Logs have multiple different Types indicating the direction or source of the movement.

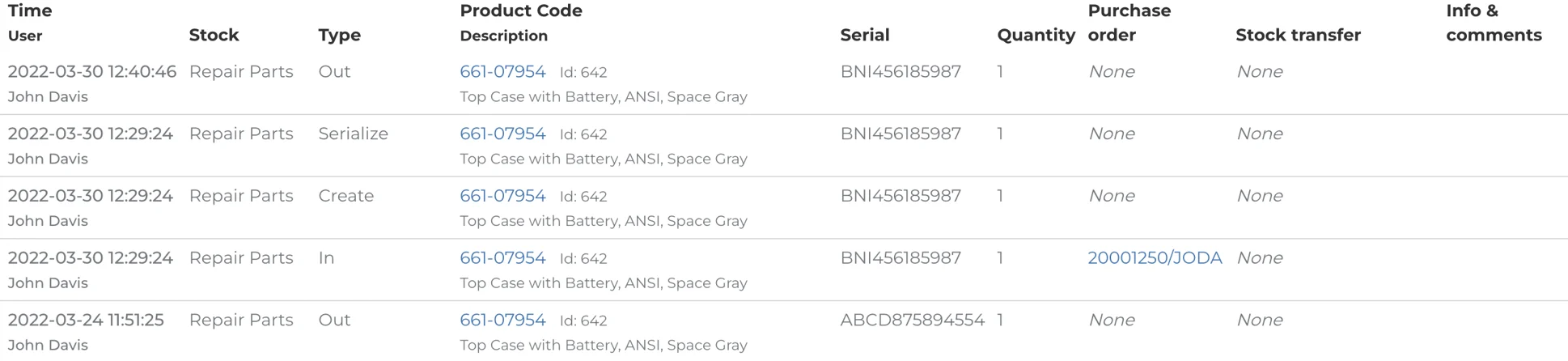

Create

-

Create entries are created the first time a Product is received into Fixably or anytime a Serialized Product is received into a Stock.

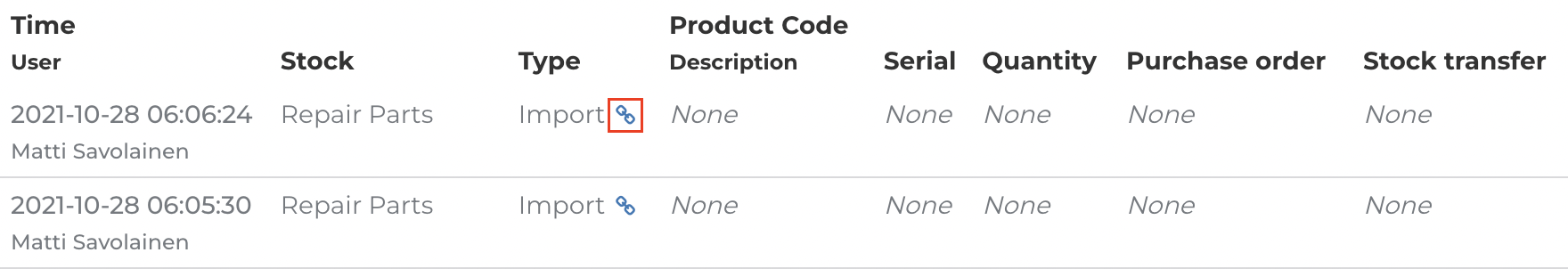

Import

-

Import entries are created when Products are received into a Stock using the Stock Import feature. You can download the Import File by clicking the import icon.

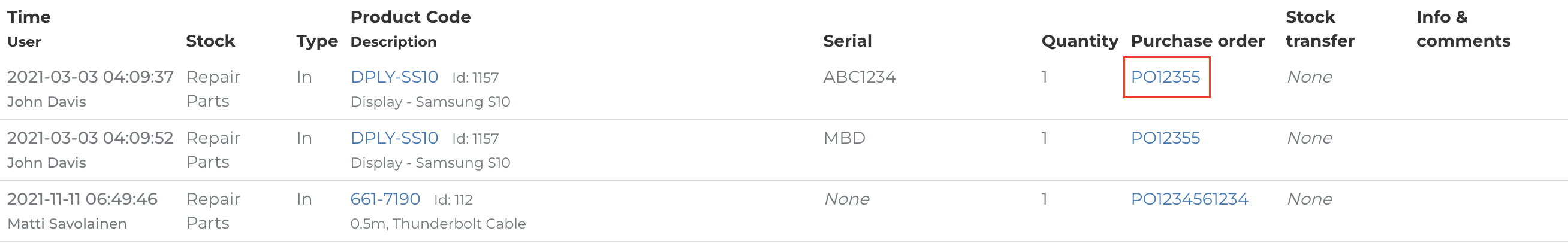

In

-

In entries are created when Products are received into a Stock using a Purchase Order. You can quickly navigate to the Purchase Order for more information about what was received.

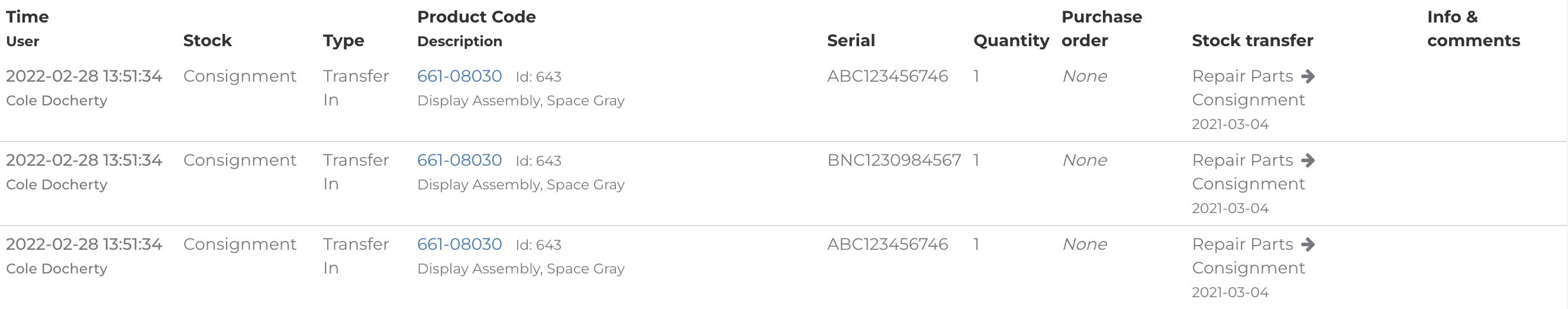

Transfer In

-

Transfer In entries are created when Products are Transferred into a Stock using the Stock Transfers feature.

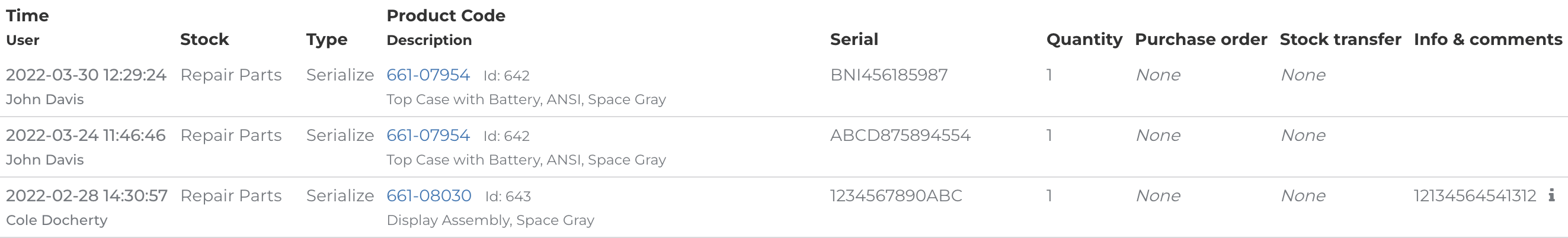

Serialize

-

Serialize entries are created when a Product is received with a Serial Number or the Serial Number is corrected after being received.

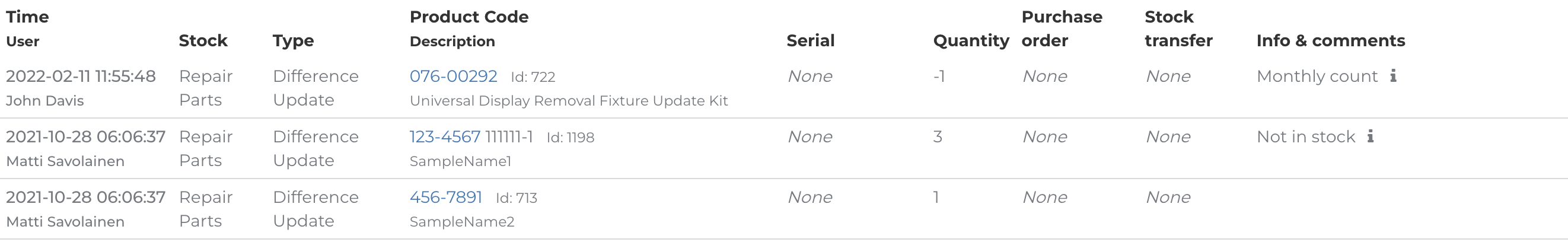

Difference Update

-

Difference Update entries are created when a Product is adjusted during an Inventory Count.

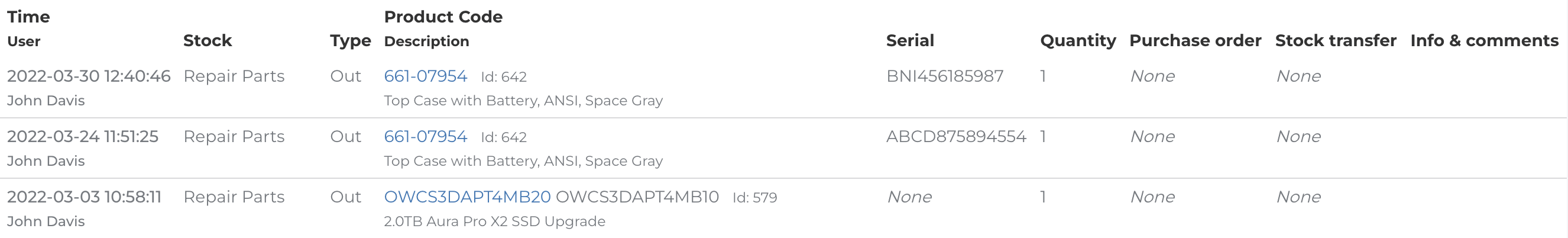

Out

-

Out entries are created when a Product is Dispatched out of Stock when used on an Order.

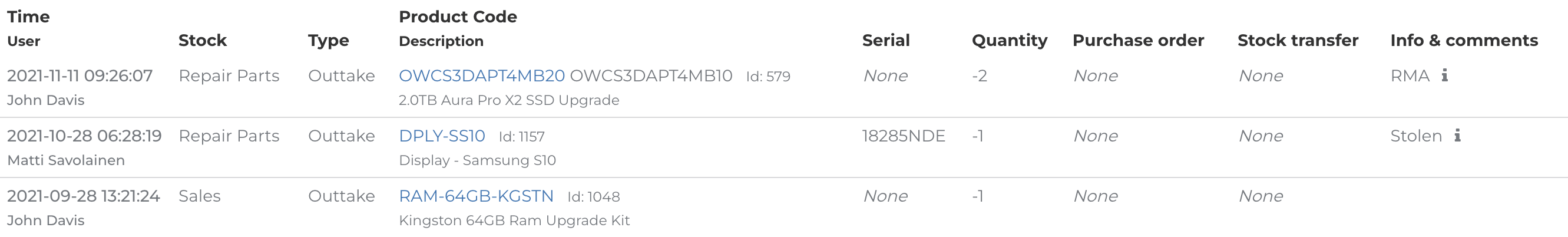

Outtake

-

Outtake entries are created when a Product is removed from Stock using the Stock Outtake feature.

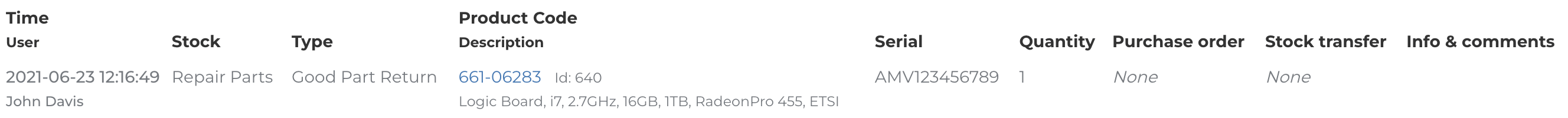

Good Part Return

-

Good Part Return entries are created when a Product is removed from Stock using the Good Part Return feature.

Transfer Out

-

Transfer Out entries are created when Products are Transferred to another Stock using the Stock Transfers feature.